Our

trade philosophy is based on the core values of excellence, integrity,

innovation, passion for results, and precise execution. We strongly

believe that the growth and success of any company are based on the

growth and success of its clients, and to have that, we ensure to follow

core values in every daily business task.

We enjoy a prominent

reputation in the market for our exceptional customer service,

reliability, and assurance regarding the delivery of quality products

within budget. We sincerely serve market leaders from various

industries, such as ordnance, glass industry, irrigation industry,

aerospace industry, chemical industry, boiler industry, and many more,

as their critical OEM partner.

Export

Our ISO

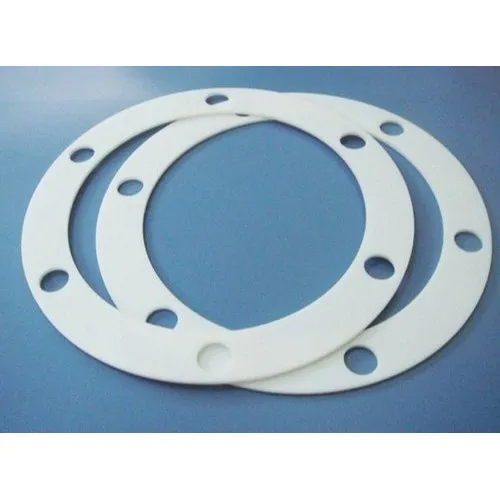

9001:2015 and 14001:2015-certified company provides a wide range of

products that are made up of UHMWPE, PTFE, and nylon raw materials. We

function with a mission to design, develop, manufacture, and market

commendable plastic components to customers in various industries. We

offer components in different colors and properties to be used across

many industries. The products we provide are tested and verified at

multiple levels by our engineers. We work hard to design and deliver

high-precision components that meet the specific requirements of our

customers. Furthermore, we are experts in providing isostatic-moulded

components that are used to produce quality engineered products.

We

enjoy an excellent reputation with customers from European, Australian,

Middle Eastern, and African countries. With increasing prospects and

interests in trade in the years ahead, we want to expand our reach to

many other countries.

New Developments

We are focused on having regular developments in our industry and developing value-for-money products.

Sheet Lining

Sheet

linings are extensively used for preventing corrosion and guarding

against the contamination of highly pure materials. They form a layer of

a distinct substance and protect the base material from abrasion. They

put the fluoropolymers' wide-ranging characteristics to good use.

Fluoropolymer-based sheet linings are praised in the market for their

chemical, thermal, and non-stick qualities, in addition to their

mechanical toughness. We employ the fluoropolymers PTFE, PFA, FEP, PP,

and ETFE for sheet lining. We provide two varieties of sheet linings:

There

are two types of sheet lining: bonded sheet lining (where the sheet is

adhered to the metal with an adhesive and the joints are subsequently

thermo-welded together) and loose sheet lining (where the sheet is

simply welded together and fitted into a piece of metal equipment).

The

advantages of sheet lining that have made it extensively demanded are

affordable prices, preservation of purity at parts per billion,

resistance to permeation, and greater durability than thermoset resins.

PTFE Powder Coating

A

dry finishing procedure has gained high popularity in the market in the

past few years. PTFE coatings are famous because of their long-lasting

nature, non-stick surface, and thin film-like coating characteristics.

As a result of their ability to provide products that can withstand low

coefficients of friction, abrasion, high temperatures, and chemical

resistance, this method is gaining popularity. The typical maximum

temperature that this kind of coating can tolerate is 260C, which is

also thought to be higher than any other fluoropolymer. Black (for

technical applications) and green (for the pharmaceutical and food

industries) are the two standard hues of PTFE powder coating.

Diaphragms (Made On CNC Machines)

Diaphragms

are essential in many different sectors, although their use in many

sectors seems simple for controlling the flow of liquids and gases. They

are used for throttling service valves,bubble-light service, chemical

resistivity owing to lining, eliminating stem leakage, and lack of

pockets to capture particles and other contaminants. We provide

diaphragms with different diameters, even in small quantities. The

diaphragms are developed with the help of CNC machines that can handle

complex designs and offer high accuracy. The diaphragms are made by us

using a two-stage procedure that extends their lifespan by 1.5 times.

PP Made Components

Polypropylene

(PP), which is created from mixtures of propylene monomers, was

polymerized in the 1950s and has since grown to be one of the most

commonly made polymers worldwide. Due to its low density and high

coefficient of friction, PP allows manufacturers to make large weight

savings. The elasticity and toughness, chemical resistance,

transmissivity, fatigue resistance, and insulation of PP are some of its

famous features. Due to its semi-crystalline makeup, PP is an easily

accessible, reasonably priced material with high strength. PP has

relative slickness and excellent resistance against absorbing moisture

when compared to other polymers. Due to the low annealing temperature of

PP and the fact that it is a soft material, cutting it demands high

precision and accuracy. As a result, we employ modern CNC machines to

precisely complete the process and give it the appropriate detailing.

This technique allows for the joining of bushes, sheets, bolts, and nuts

to develop the desired component.

Vessel/Tank Lining

Linings

are one of the most traditional maintenance options for protecting

against chemical, corrosion, and erosion threats. With the use of proper

linings, the vessel or tank can be developed from inexpensive and

easily formed materials. We provide lining services by making use of a

variety of fluoropolymer materials. Our procedures are affordable,

simple to use, and prevent corrosion while also extending the life of

assets without the need for hot work and improving efficiency. The use

of lining has proven its ability to lower maintenance, operational, and

replacement expenses. They possess high resistance to explosive

decompression and have tenacious adherence to a range of substrates, in

addition to offering outstanding resistance to heat and chemicals. As

required by customers, with the support of our group of highly qualified

professionals, we provide recommendations on vessels and tanks.

PFA / FEP Lined Components

Many

companies experience a variety of difficulties while handling and

treating wastes and effluents that consist of extremely caustic and

pristine media. The lifespan of traditional systems is affected by the

high temperatures and pressures. Due to these circumstances, there is a

heavy requirement for piping and equipment that have an anti-corrosive

surface and the suitability to have chemically aggressive components,

regardless of composition rate. Due to their chemical inertness, PFA and

FEP lining materials are used to treat such issues. The majority of

corrosion issues can be resolved with these materials. This approach is

secure, economical, and environmentally friendly. These fluoropolymers,

like others, are capable of withstanding corrosion from more types of

chemicals at a range of pH levels and concentrations.

Specially Blended Grades Of PTFE

It

is fairly common to blend polymers with additives. Combining PTFE

compounds minimises cold flow under pressure and abrasion in dynamic

applications requiring contact with paired surfaces. Fillers are

typically grouped into:

Inorganic Fillers: As inorganic fillers

have a greater frictional coefficient than PTFE, such as bronze,

charcoal, graphite, glass fibre, MoS2, stainless steel 316, aluminium

oxide, mice, calcium fluoride,etc., additional internal lubrication is

needed to minimise friction.

Organic Fillers: Compared to inorganic

fillers, organic fillers such as polyphenylene sulphide, polyimide, and

polyether ether ketone (PEEK) have high resistance against temperature.

They also cause a smaller rise in the frictional coefficient. In this

situation, further internal lubricant additives are typically not

necessary for PTFE compounds.

Pigmentation: For a variety of

purposes, many industries demand pigmented (coloured or dyed) fillers to

develop colors such as red, blue, green, and yellow.

In order to

acquire the necessary mechanical, electrical, thermal, and tribological

qualities, we at Electro Polymers Industries process the fillers. With

these characteristics, hardness and thermal conductivity are raised,

wear resistance is improved, and the linear coefficient of thermal

expansion and contraction is decreased.

Over time, we have grown

our product line and started selling many raw materials, such as UHMWPE

and Nylon. In the initial days of business, we commenced with just a few

PTFE-made raw materials. We are currently working on PP and PVDF

component development. Other development projects are also in progress;

details will be released soon.

Our Team

A

team of creative and knowledgeable professionals supports our business.

Our exceptional success in this industry is completely a result of

teams commitment. These professionals are knowledgeable enough to

recognize and appropriately meet the needs of our clients. Our

professionals are adept at managing challenging circumstances and

offering a unique solution within a set time. Our workforce is made up

of engineers, quality inspectors, purchasing agents, skilled and

unskilled labours, and sales and marketing personnel.

Quality Assurance

Both

product quality and client satisfaction are given top importance by our

business. To grow as a reliable business in the industry, we have

created a thorough and sophisticated quality testing unit. This section

includes modular testing apparatus and equipment, which enable us to

cross check the defect-freeness of UHWMPE Chain Guide, ELPOL PTFE Block,

Lined Pipe Fittings, ELPOL PTFE Machining Parts, etc. Our facilities

are routinely upgraded and maintained to ensure continuity in our

business operations. In order to protect these products from damage

while in transit, we also provide strong packaging.

Infrastructure

An

advanced and spacious processing facility is located close to

Ahmedabad, Gujarat, on the west coast of India. The area occupied by

this facility is 35,000 square feet. This facility includes a

manufacturing unit, a quality-testing unit, a storage and packaging

unit, etc. for the smooth and efficient flow of connected activities. We

have updated the manufacturing equipment and technology at our

production site to increase both the quality and the production rate.

Our highly qualified employees efficiently operate the machinery that

has been installed, assuring the prompt manufacture of goods of the

highest quality.

Why Us?

Due

to our high-tech internal facilities and team of competent

professionals, we are able to satisfy the needs of our clients and excel

in this field. The following are additional variables that contribute

to our extensive clientele in the market:

- A cutting-edge infrastructural facility and extremely skilled professionals.

- Strict requirements for quality and client-centered strategy.

- Customizing capability and reputable business practices.

Brands We Deal In

All our products are available under the brand name ELPOL.

Industries We Serve

- Aerospace Industries

- Automotive Industries

- Chemical Process Industries

- Construction Industries

- Conveyor Industries

- Food Beverage Industries

- Food Processing Industries

- Industrial Market Industries

- Medical Industries

- Oil & Gas Industries

- Semi Conductor Industries

- Water & Environmental Industries

Mission and Vision

Thanks

to our resources for manufacturing cutting-edge work, some industrial

applications based on specially created technology are also prepared.

You

must be fully informed as to how this false belief praise functions and

instructed on how to use the truth's proper teachings.